- Home

- Slip Ring Power Transmission

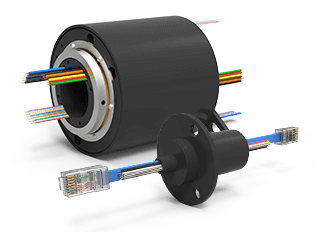

Custom Slip Ring Solutions for Precise Power, Signal and Data Transmission

Slip Rings for Power, Signal and Data Transmission – from Standard to Custom Designs

Efficient energy and signal transfer in rotating systems requires reliable slip rings. Whether for high-current, sensitive signal or data transmission – our solutions offer precision, durability and flexible customization.

Applications

Our slip rings are used in a wide range of industries:

- Wind and solar energy (rotor blades, towers)

- Aerospace and medical technology (e.g. CT scanners, surgical lamps)

- Radar systems, surveillance cameras, revolving doors

- Automation, packaging and heating technology

How Slip Rings Work

A slip ring connects stationary and rotating components through contact-based transmission. For high-current applications, we use materials such as brass with silver-graphite or precious metals. For sensitive signals and data, special brush technologies minimize resistance variation and ensure signal integrity.

Custom Slip Ring Design

Designing a slip ring involves both electrical and mechanical considerations. Especially in applications with high data rates and Ethernet signals, effective high-frequency shielding is crucial to protect signals from electromagnetic interference (EMI), often caused by motor current paths. A separate, well-grounded shielding layer within the slip ring ensures data integrity even during rotation.

Key technical challenges include:

- Electromagnetic compatibility (EMC)

- Impedance matching for high-frequency signals

- Minimal contact noise (contact resistance)

- Stable signal transmission with minimal packet loss

Environmental conditions must also be considered. Dust, water, vibration and temperature affect the choice of materials, sealing and contact technology. Mechanical factors such as rotation speed, mounting and available space further influence the design.

Essential selection criteria:

- Type of transmission: power, signal, data or media

- Connection and installation options

- Protection class, shock and vibration resistance

- Service life and maintenance requirements

The result is a slip ring that is technically reliable, durable and precisely matched to your application.

Reach Out to Us!

We will be happy to advise you on selecting and developing your ideal slip ring solution.

Checklist

Questions for successful solution

| What is the operating environment? Is sealing required to prevent contamination? |

| What media must be considered, such as water, dirt, mud, or other atmospheric conditions? |

| How many electrical channels do you need? |

| What should be the voltage and current for each channel? |

| What data protocol do we use? |

| How should the slip ring be connected to your system - lead wires or connectors? |

| Do the slip rings need to be grounded? |

| How will the slip rings be attached to the system? |

| How fast does the slip ring rotate? Does the direction of rotation change? |

| How busy is the channel? |

Peter Schärer

Managing Director

Applications and Technical Sales

Slip Ring Product range

TDS Precision Products GmbH has a wide variety of products available for you in its product range. We offer encapsulated and open slip rings in various standard designs. For example, you can find an encapsulated slip ring for current transmission in the "EST Series". It forms the standard type with ten amps and 600 volts. Depending on your needs, you can choose between six and 24 rings. Some models transmit both current and signals and are therefore suitable as combination slip rings. These include the "ESM Series", which provides up to 52 rings. A modular, open slip ring for current transmission up to 20 amperes can be found in the "E Series". It convinces with high durability and uses a hollow shaft between 25 and 60 millimeters.

Miniature Slip Rings

High Power Slip Rings encapsulated

Ethernet Slip Rings capsules

HD Video Slip Rings

PIN Slip Rings

Hollow shaft slip rings

Large Hollow Shaft Slip Rings

Ethernet Slip Rings Hollow Shaft

High Power Slip Rings Hollow Shaft

Modular Slip Rings

Rugged Slip Rings

High Speed Slip Rings

High Temperature Slip Rings

Flat encapsulated slip rings

Disc Slip Rings

Open slip rings

Rotary connector

Customized slip rings